This is a combined interview with Anna Shields, General Manager, Heather Fuston, Business Development & Marketing Manager, and Victoria Taylor, Owner.

“Dairy production on a large scale is a commodity, and we believe that takes so much of the connection out of it. Satisfying a bottom line makes the product about money—not the customer, not the farmer, and not the processing. Even though it’s the norm for the dairy industry, most dairy production today has moved far away from what dairy used to be.

Our co-founders saw a beautiful supply of milk in this area that was unlike anything on the shelves at the time. There weren’t good options for milk, so they set out to provide consumers with something better.

Dairy is this wholesome and alive substance, and you can really only recognize that value with good milk, and good milk starts at the farm. With that in mind, we source from small local family farms that grass-graze their cows. Good milk is made by good farms with healthy cows.

We are the connection point between the farm and the consumer. We provide an option for the farmer to sell their milk and we make sure production is doing right by the cows, doing right by the farm, and doing right by the soil.

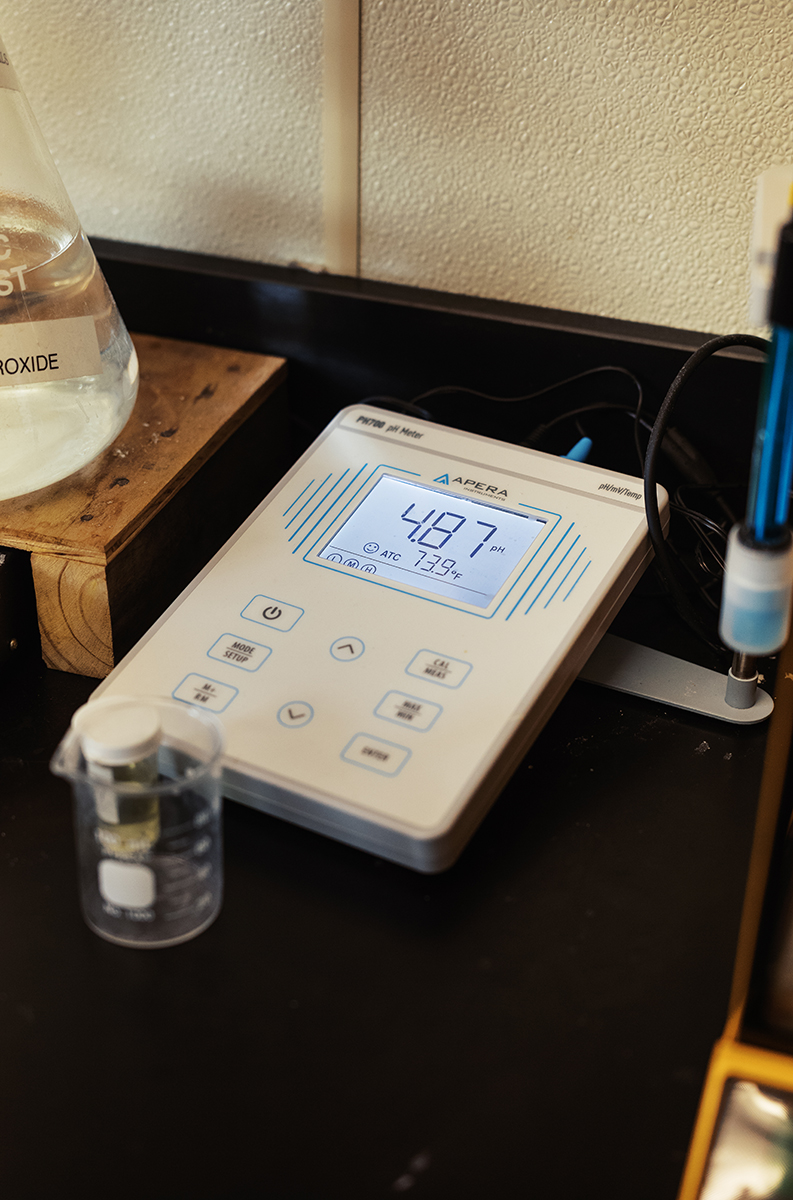

We make sure that we are processing the milk as gently as possible. In the state of Ohio, you can’t sell raw milk, so we pasteurize our milk by using the lowest temperature allowed by law. We also don’t homogenize our milk, so the cream naturally rises to the top because that’s what it’s supposed to do.

When we first started, we would get some older customers that would drink it and sometimes have tears in their eyes and say, ‘This is what I grew up with.’

An important current consumer trend is to use buying power for good—they want to know that what they’re buying is not only good for them but good for others and what they’re working towards in life. Whether that’s the environment, whether that’s family, whether that’s quality.

We’re right in the middle of that: providing a really great source of milk from the farmer, giving them a price that allows them to thrive, and then bringing wholesome, premium, decadent dairy to our customers.”

–Anna Shields, General Manager; Heather Fuston, Business Development/Marketing Manager; Victoria Taylor, Owner

“A2 protein is a naturally-occurring protein in cow’s milk. It’s also naturally occurring in human, sheep, and goat milk. People that have lactose intolerance, or are just digestive upset when they drink milk, most often find that they can drink A2 milk because our bodies are acclimated and have evolved to digest it.

Years ago, all cows used to have only A2 protein, but somewhere along the line, a genetic mutation occurred and they started to also produce A1 protein in their milk. Now, the difference is most cows produce A1 or A2 or a combination of both.

Our farmer only breeds his cows to produce A2 protein in their milk. Sometimes people ask how that can happen, and it’s nothing where the cows are being genetically altered or anything. Our farmer just breeds for A2 only, and it’s like a blood type similar to breeding pure-bred dogs—either the cows have it or they don’t.

Getting to the roots of good dairy means it’s just A2 milk, that’s certainly part of it. But it also has to do with what those cows are eating and how the milk is being processed. We found that minimally processing the milk seems to make it easier to digest as well. The more you cook something, the more it changes and the more our bodies say, ‘This is not a real food.’

Milk is a live substance and has a lot of live enzymes in it. With conventional dairy, companies are trying to ship it as far as possible. Shipping a real, live substance from one coast to the other is hard and doesn’t support those live enzymes. So, we allow the milk to be the wonderful, natural substance that it is. We keep it fresh and alive. That also means we have to keep it local. Sterilized milk that can last six to nine months on the shelf is frightening. We like to think of ourselves as the anti-shelf stable option.”

–Anna Shields, General Manager; Heather Fuston, Business Development/Marketing Manager; Victoria Taylor, Owner

“One of the challenges of producing milk like this is a shorter shelf-life, so we work within a distribution range where we feel comfortable. Outside of that range, with milk especially, it’s just really not possible to ship it in a timely manner and get it on the shelf in a time frame that’s acceptable. Customers don’t want to pick up a carton of milk that has two days left on it.

Another challenge is the scale that we’re at. We are in this difficult in-between stage where we’re too small to work with some retailers or co-packers and too big to work with others.

Then, of course, you have the challenges of working with the corporate grocery industry. There you are competing with other brands that can ship milk at high volumes across the country at a lower price.

It’s a challenge from the very beginning of the entire process, too. Our farmer must farm in a certain way and cannot use certain things that go against what we’re trying to provide to the consumer. Then, once the product gets here and into our plant, sometimes that means extra steps to have a quality product. For example, when you are creating a coffee drink with dairy, it’s easier to use a syrup that has a stabilizer in it – but we don’t do that. In those cases, we’re investing in local coffee or we’re investing in our employees to take the time to make that syrup in-house.

We’re utilizing milk the way milk should be used, to bring really good things to people every step of the way. There’s a process and cost to it, but with that, you’re providing good lives for your employees, your farmers, and your customers.

I like to refer to it as an enrichment circle, and it happens every step of the way. It starts on the farm with the standards we set to give our consumers what they ask for. Then in the plant, sure, we could pasteurize milk at higher temperatures. That would be a turn of a dial on the machine, and that would let us meet more of these market demands. But we won’t do that because it does not support the enrichment of what we’re setting out to do.

We’re in Appalachia. We’re in one of the poorest counties in the state of Ohio, so that enrichment circle also includes resources, talent, and more. We like to say we are a grassroots micro creamery. This creamery was built with all used equipment. Our main structure is an old, double-wide classroom trailer. We’re utilizing milk the way milk should be used, to bring really good things to people every step of the way. There’s a process and cost to it, but with that, you’re providing good lives for your employees, your farmers, and your customers.

There is an education piece to that with the consumer as well because we are different. We fill a niche that is different from what you would typically see on the shelf. Part of our job is to let people know why we’re different, why they need us in their lives and why this product is better.”

–Anna Shields, General Manager; Heather Fuston, Business Development/Marketing Manager; Victoria Taylor, Owner

“When you know better, you do better. Other companies are already making processed and mass-produced products. If we did that, there’d be no reason for us to exist if that’s all we were going to do. There are bigger companies that already do that.

We know that milk with only A2 protein is better for digestion and it’s more compatible with the human body. We know that it’s better for the cows to be out on the grass. When we first started, that’s all we knew; that it was better for the cows and that it made beautiful tasting milk. It’s actually more wholesome and better for people, too. Our milk is higher in conjugated linoleic acids and omega-three fatty acids.

We have seen a change with customers in the last several years from customers wanting fat-free or reduced-fat milk to wanting more whole milk. People understand now that’s where the good stuff is.

We produce about 6,000 gallons a week, which means we are bigger than a micro-dairy but smaller than any other dairy that you might know the brand name of. We often say we’re too big to be small and too small to be big.

Our biggest sellers are whole milk and our full line of yogurts. We have plain full-fat yogurt, plain reduced-fat yogurt, vanilla yogurt, and maple yogurt. You’ll see very clean labels on each of those because it’s made with just the highest quality vanilla and maple syrup that we could find and added to the yogurt. We also have some co-packed cheese that we use the A2 milk in, but we aren’t big enough to do that here, so we have it packaged for us by another facility. We also have some cheese cracker crisps, that are just cheese melted down to become more like crackers. Those are so delicious.”

–Anna Shields, General Manager; Heather Fuston, Business Development/Marketing Manager; Victoria Taylor, Owner

“Our milk comes down from our current farm in Millersburg, Ohio. It all comes in on the same truck. We bring all of our milk in a fluid state. For our yogurt, specifically, we use nano-condensed milk. For our nano-condensed milk, what we do is put it through a series of filters, that essentially pushes all of the water out of the milk. After that, you have this concentrated milk product. It’s not adding anything, it’s just simply removing the water from the milk.

Then we’ll take that nano-condensed milk and add our cream and yogurt cultures to it. We put it in this big bath pasteurizer tank to start the culturing process and it will set in there overnight. The next morning, we run it through our yogurt filler.

At the heart of it, it’s a connection process. We’re connecting people to their food.

At the heart of it, it’s a connection process. We’re connecting people to their food. Just the other day we had a family travel all the way from Pittsburgh, just so that they could show their kids where the milk they put on their cereal comes from.

We’re in such a unique environment and stage in society where consumers want to know where their food comes from. They want to be rooted with their suppliers or the people that they buy their food from. Anytime that we can help connect those things for people by providing really good products or being able to say where our ingredients come from, that is really helpful.”

–Anna Shields, General Manager; Heather Fuston, Business Development/Marketing Manager; Victoria Taylor, Owner

“The culture and environment here are amazing. One of the reasons I’ve been with Snowville for so long is because not only do they provide a wonderful living wage, but they also support me in so many different ways. I’m a mom of two boys and they make sure that I have plenty of time to spend with them through a flexible schedule and things like that.

The culture here is super fun and we’re always out there doing events and demos. We have the ice cream bike that we take to a lot of different events. So, we bring the party, bring the dairy and let people know that milk is so much more than that $2-gallon jug on the shelf that we’re kind of used to. We’re here with intention, fun, and a good cause.

One of the things that I love about this community is how supportive it is of small businesses, but especially food businesses. There’s a lot of really great food-driven businesses coming out of this region.

That’s because the community here embraces it and really does put their buying power behind it and help to launch these products. I’m not sure if we would have done as well anywhere else, because we’ve really got our footing here in this community. We’ve received a ton of support and it has just spread from there. Our customers are so loyal. We call them our ‘Snowvillians’ are very loyal.

We set out, in theory, to revolutionize the dairy industry.

When we first started, we were the only one on the shelf. Now, I like to think of it like if there are more options for consumers, then we are doing something right. We set out, in theory, to revolutionize the dairy industry. With more options, we might not be capturing all the sales, but we’re promoting good things that people are being conscious about.

We want to continue to say yes to more things that allow us to keep doing what we’re doing and promoting these efforts. We want to promote the things that allow us to preserve this craft and thrive for years to come.

The future looks good and we are seeing that people want good milk, from quality sources. Because we are built from a double-wide trailer and used equipment, expansion can be a real challenge. We’re at the point now where we want to say yes to more things. We get calls about adding products or expanding. So, it’s being able to say yes to more opportunities for consumers, employees, and our farmers.”

-Heather Fuston, Business Development and Marketing Manager

“I’m originally from California and I didn’t move to this area until I was 40. When I had kids, I wanted to raise them in a place where they could play outside in open fields and in nature. I’m glad I raised my children here. My daughter is now a farmer, too.

I would not go back to Southern California and I find it to be beautiful here. I love having the seasons, which I didn’t have before. In Southern California, you have the same weather every day and there’s no variety. Here, when those first bulbs come up in the spring, you’re so ready to see that and there’s such a variety in the seasons. Then it’s absolutely beautiful in the summer and the fall.

I often make the joke, it’s like being in an elevator where every time you open the door, it’s something different.

My commute to work is way better than when I was on the freeway in LA. The commute to work just makes me happy every morning. I’m just happy to be here.

In the future, we want to get our volumes up so we can support more people and more farmers. We are a fresh product and thus, we don’t travel well. Because of that, we need to just get the word out and educate more people on the fact that we are here, who we are and what we do so they can take advantage of what we’re producing.

When we first came online, the dairy industry didn’t want differentiated milk. You had the ‘Got Milk’ campaign and within the industry, their catchphrase was ‘milk is milk.’ In other words, your milk is no different than my milk.

However, we’ve established that there is a difference in grass-fed milk and in what we do.

Something else that we’ve been really trying to do is giving back to others based on our values and in solid ways. We are looking at certifications and humane verifications or non-GMO labeling. Certifications like that add validity to our products for our customers and give them transparency into our practices.

Then we also give back to our community in the form of product donations and really investing in causes that are near and dear to our hearts.”

-Victoria Taylor, Owner of Snowville Creamery

Pomeroy, Meigs County

#WeAreOhioSE